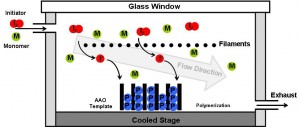

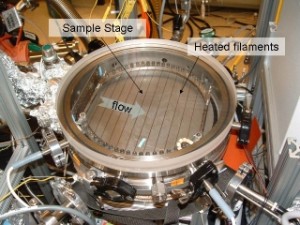

Polymer thin-films can be successfully deposited by initiated-CVD (iCVD). iCVD is a solventless, all-dry process which enables deposition of conformal polymer coatings on delicate substrates (i.e. fabrics).

Polymer thin-films can be successfully deposited by initiated-CVD (iCVD). iCVD is a solventless, all-dry process which enables deposition of conformal polymer coatings on delicate substrates (i.e. fabrics).

The initiator radicals are formed by the thermal decomposition of the initiator by heated filaments. Polymerization takes place on the surface and is initiated when the gas-phase initiator radicals attack the adsorbed monomers on the surface, creating monomer radicals. The polymerization is terminated either by capping of the polymer chains by the initiator radicals or by coupling of polymer chains. This technique was first developed by Prof. Karen K. Gleason at MIT.

* Organic and inorganic thin-film deposition using chemical vapor deposition.

* Fabrication of 3D nanostructures for biosensor and drug delivery applications.

* Solution phase metal nanoparticle synthesis and fabrication of hybrid thin films.

* Deposition and improvement of anti-fouling coatings for reverse osmosis membranes and biomedical applications.

Fabrication of Polymer Nanostructures:

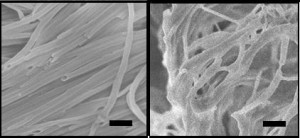

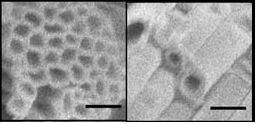

Conformal nature of the iCVD technique enables us to fabricate high aspect ratio polymeric nanotube structures. Polymer nanotubes with their defined shapes and sizes and enhanced performance have a wide range of potential applications, such as templates for protein studies, due to their large surface area to volume ratio providing numerous protein immobilization sites or tissue engineering substrates. We use AAO membranes as templates and after the coating, we etch the membranes completely to release the nanotubes. By controlling the deposition conditions, chemical and mechanical properties of the nanotubes can be tuned for specific applications. Hydrogel nanotubes of different swelling ratios can be used as templates for protein attachment studies.

Conformal nature of the iCVD technique enables us to fabricate high aspect ratio polymeric nanotube structures. Polymer nanotubes with their defined shapes and sizes and enhanced performance have a wide range of potential applications, such as templates for protein studies, due to their large surface area to volume ratio providing numerous protein immobilization sites or tissue engineering substrates. We use AAO membranes as templates and after the coating, we etch the membranes completely to release the nanotubes. By controlling the deposition conditions, chemical and mechanical properties of the nanotubes can be tuned for specific applications. Hydrogel nanotubes of different swelling ratios can be used as templates for protein attachment studies.

Related reference:

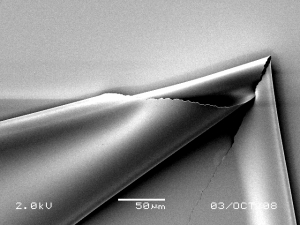

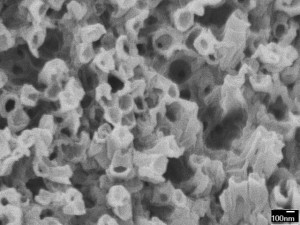

Bifunctional Coaxial Nanotubes:

The templated iCVD technique can also be used to fabricate bifunctional coaxial nanotubes. We synthesized a coaxial nanofilm with a hydrogel  core and a shape memory shell to form temperature activated nanotubes. We then load these coaxial nanotubes with dye molecules and study the burst release mechanism due to the stress applied by the shape memory outer layer.

core and a shape memory shell to form temperature activated nanotubes. We then load these coaxial nanotubes with dye molecules and study the burst release mechanism due to the stress applied by the shape memory outer layer.

Collaborators: Prof. Karen K. Gleason (MIT) and Prof. Melik C. Demirel (Penn State).

Related reference:

Sensor Applications:

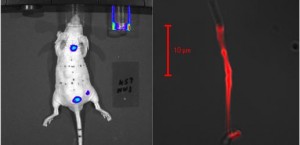

The hydrogel nanotubes can also be used for in-vivo sensor applications. We fabricated microworms for in-vivo monitoring of sodium imbalance, using the hydrogel nanotubes. The microworm sensors have an optode core and a hydrogel coating to protect the core. The microworms are placed under the skin and thus, the fluorescent core enables the monitoring of the sodium imbalances by the patient without the need for invasive tests.

The hydrogel nanotubes can also be used for in-vivo sensor applications. We fabricated microworms for in-vivo monitoring of sodium imbalance, using the hydrogel nanotubes. The microworm sensors have an optode core and a hydrogel coating to protect the core. The microworms are placed under the skin and thus, the fluorescent core enables the monitoring of the sodium imbalances by the patient without the need for invasive tests.

Collaborators: Prof. Karen K. Gleason (MIT), Prof. Heather A. Clark (Northeastern Univ.) and J. Matthew Dubach (Northeastern Univ.).

Related reference: