Comments Off on DİMAP – Direct Digital Manufacturing Platform project is in progress

APRIL 17TH, 2024

By SERRA TOPAL

DİMAP – Direct Digital Manufacturing Platform project which officially started with its Kick-off Meeting on 25rd March 2023 has been advancing at its full speed.

The project is funded by EC IPA-II (Instrument for Pre-Accession) CISOP (Competitiveness and Innovation Sector Operational Programme) through Ministry of Industry and Technology (MoIT) of Turkey.

Direct Digital Manufacturing Platform (DiMAP) which will be integrated and will expand within the Sabancı University Integrated Advanced Manufacturing Centre (SU-IMC), is aimed to be an innovative digital AM platform for quality control, testing and characterization of data-driven smart manufacturing systems within the current center. Thus, this platform will help and transform SMEs by enabling and uplifting them to manufacture high value-added functional parts. In certain applications, with the help of DiMAP, the pilot-scale products or product groups of SMEs will be extended up to TRL-7 (demonstration of the prototypes in operational environment).

The Project is composed of Technical Assistance and Supply Components. TA is being conducted by Frankfurt School of Finance and Management. Within the project, 18 different equipment under 8 LOTs are supplied.

- Lot 1: Additive Manufacturing and Post Processing Equipment (EBM, high Pressure dynamic gas cold spray, tube furnace, ball milling system, CNC lathe)

- Lot 2: Material Characterization Equipment (XRD, Microstructure specimen preparation)

- Lot 3: Mechanical Testing And Characterization Equipment (Hardness tester, Creep tester, Tribometer)

- Lot 4: Metrology and In-Situ Monitoring Equipment (3D scanner, ultrasonic immersion system)

- Lot 5: Microscopy Equipment (SEM with FIB)

- Lot 6: X-Ray Computed Tomography (X-CT)

- Lot 7: Wire EDM

- Lot 8: High Cycle Fatigue Tester

Target groups:

• SMEs

• Start-ups

• Companies

• Institutions

• Universities, R&D and Design Centers

The Inception phase of the Technical Assistance is completed in October 2023. The supply deliveries, installations and supplier trainings have been ongoing since January 2024.

Stay tuned for announcements on metal AM trainings for SMEs and professionals, also networking, Tech Challenge and collaboration events!

OCU Team: OCU Director: Talat Durgut (SU ATT), Deputy OCUD: Devrim Ozaydin (SU IMC CTCE CEO), Techn Leaders: Dr Serra Topal, Bora Gönül, Deputy Techn leader: İlayda Erkul

#additivemanufacturing #engineering #advancedtechnology #coldspray #aerospace #automotive #digitalmanufacturing

Comments Off on Our 1003 Research Project Is Completed!

NOVEMBER 23RD, 2023

By SERRA TOPAL

Our large-scale 1003 project titled “The application and optimization of atmospheric plasma activation technique onto large-scale thermoset and thermoplastic composite adhesion systems using robotized multiple nozzle heads” is completed officially on 26th October 2023. The closure report was submitted on September 1st, 2023.

The project team included Dr. Serra Topal (Sabanci University IMC CTCE) as PI, Assoc. Prof. Dr. Bertan Beylergil (Alanya Alaaddin Keykubat University), Dr. Cem Öztürk (Kordsa A.S.), Assoc. Prof. Dr. Burcu Saner Okan (Sabanci University) and 2 PhD and 2 MSc students.

Within the scope of the project,

- the effect of atmospheric plasma activation on the overlap regions of bonded systems for aerospace grade thermosetting and high Tg thermoplastics CFRPs are demonstrated on laboratory level

- CFRTP composites with AFP-production and autoclave consolidation are demonstrated, their ASTM standard coupon & bonded system testings are completed

- Low void content CF/PEI composite production with vacuum assisted hot press consolidation is succeeded and their ASTM standard coupon & bonded system tests are completed

- Thermoset- and thermoplastics-compatible adhesive film development and prototyping stages are completed, successful serial production is achieved

- Numerous research articles are submitted and published.

- Yildirim C., Tabrizi I.E., Al-Nadhari A., Topal S., Beylergil B., Yildiz M., “Characterizing damage evolution of CF/PEKK composites under tensile loading through multi-instrument structural health monitoring techniques”, Composites: Part A, September 2023, 107817. DOI: 10.1016/j.compositesa.2023.107817

- Yildirim C., Ulus H., Beylergil B., Al-Nadhari A., Topal S., Yildiz M., “Effect of atmospheric plasma treatment on Mode-I and Mode-II fracture toughness properties of adhesively bonded carbon fiber/PEKK composite joints”, Engineering Fracture Mechanics, 289: July 2023, Article ID 109463. DOI: 10.1016/j.engfracmech.2023.109463

We would like to thank you to the team from the earliest stages of proposing, writing and conducting this project and the funding institution Scientific and Technological Research Council of Türkiye (TÜBİTAK), its staff and our Project Office staff for their support.

Comments Off on Our 1001 Project on 3D woven composites is completed!

MARCH 1ST, 2023

By SERRA TOPAL

Our 3-year 1001 research project is closed in February 1st, 2023, which was funded by The Scientific and Technological Research Council of Turkiye. Now it is time for the report submission, and dissemination activities which are not limited to: two ready-to-submit journal articles, and one submitted conference proceeding.

It was an enlightening experience for us to:

- design the 3D woven fabric architecture with TEX-TECH aiming for an increased performance in dynamic loadings up to 150 J impact

- investigate the novel damage behavior and sequence occurring in the inter-ply hybrid and intra-ply hybrid 3D woven composites under flexure loading

- work on advanced VARI to produce highly impregnated fabric

- conduct extensive meso-scale and macro-scale finite element analyses on the unit cells and tested components

Stay tuned for the updates and forthcoming papers and new projects on these materials to further extend the know-how!

#engineering #3dwoven #textilecomposites #impactperformance #aerospace

Comments Off on Our research on nano-modified aircraft repair technologies is published in Carbon

DECEMBER 21ST, 2022

By SERRA TOPAL

I am very pleased to share the news that our research article on the improvement of the scarf repair performance of aircraft secondary structures with nanomaterials has been accepted and published in the CARBON journal.

I would like to thank Professor Mehmet Yildiz and Dr. Serkan Unal, engineers and staff of our Sabanci University Composite Technologies Centre of Excellence laboratories, our PhD fellows and interns, Turkish Airlines Technic structural repair unit engineers and staff, Kordsa Inc., and our collaborative partner RWTH Aachen University for making this project real.

#nanomaterials #aerospaceindustry #aerospace #engineering #cfrp #composites #cnt #graphene #nanotechnology #prepregtechnologies #compositerepair #repairandmaintenance

Feel free to access the paper here: 10.1016/j.carbon.2022.12.056

Comments Off on “Automated Repair Patch Production for Composites” project has been completed!

DECEMBER 10TH, 2020

By SERRA TOPAL

ARP2 project which was a dual collaboration of Sabanci University in Turkey and RWTH Aachen University in Germany has been completed (June 2017-2020) and its final report is accepted.

The project provided a rich insight in CFRP repair in accordance with Structural Repair Guidelines and allowed us to experience the repair of primary and secondary components of aircraft in their real implementation environment thanks to Turkish Airlines Technic, in Sabiha Gokcen Airport area. Along with the project 1 undergraduate intern, 1 undergraduate student, 2 graduate interns, 1 MSc student gained hands-on experience on composite repair, 2 MSc. students graduated within the scope of this project, 2 PhD students actively participated in nanomaterial functionalization and 3 postdocs participated in various work packages. A pilot-scale nano-integration unit was constructed and actively used for providing master batch for the nano-modified carbon fibre reinforced thermoset prepreg production line of Kordsa A.S. After the pandemic, it was possible to transfer this know-how to the Sabanci University Integrated Manufacturing Technologies Application and Research Center (SU IMC) – Composite Technologies Center of Excellence (CTCE), for the completion of aircraft repair procedures in the lab infrastructures.

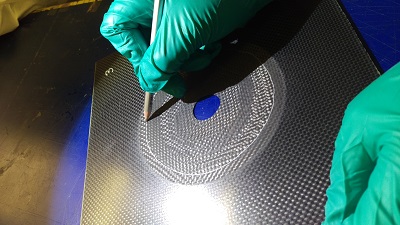

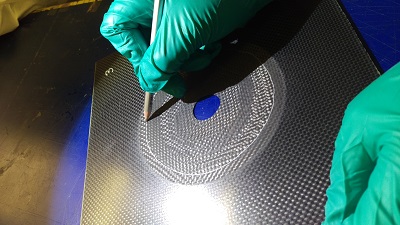

Further, significant efforts were given to automatize the ply-by-ply engraving of the CFRPs with KUKA robot at the SU IMC research center with high precision with limited time constraints, which was also performed by RWTH Aachen University simultaneously.

The corresponding research articles are being prepared for publication for further exploitation of the results to the scientists, researchers and other end-users. Many thanks to our researchers, students, our collaborators Kordsa A.S. and its project leaders, Turkish Technic and aircraft structural repair unit leader, atelier leaders and technicians; and the administrative-technical staff at the SU IMC CTCE for their efforts, valuable recommendations and patience.

November 2020

Comments Off on Citations page being updated – Stay safe & healthy during COVID-19

APRIL 2ND, 2020

By SERRA TOPAL

Recent citations to my articles are being added to my Citations page (with their DOI links) for further dissemination of knowledge for global researchers and students.

As many countries and people have been suffering severely from novel Corona virus 2019 (COVID-19) since January 2020, I am wishing health and safety to everyone and their families in all countries, and feeling the overwhelming gratitude for the medics and other supporting workers in the health sector at these difficult times.

Comments Off on My 1001 Research Project is accepted for funding

AUGUST 30TH, 2019

By SERRA TOPAL

Good news: My research project which I proposed in March 2019 passed the evaluation in MAG (Engineering Research Group) and is accepted for funding by The Scientific and Technological Research Council of Turkey.

Our project aims for the production, modeling, characterization and testing of innovative 3D woven composite materials for the use of high performance applications.

Project team consists of Dr. Hatice Sinem Sas Cayci (Sabanci University FENS&IMC CTCE) who is an expert on resin flow optimization in complex fibrous reinforcements and Dr. Adnan Kefal (Istanbul Technical University) who has exceptional experience in finite element analysis and homogenization methods.

The project duarion is 3 years with a budget of 720.000 TL.

Comments Off on Good news from Aeronautics & Aviation calls: Our 1003 Project is accepted for funding

JULY 5TH, 2019

By SERRA TOPAL

Our 3-year large-scale Aeronautics and Space Innovative Technologies project which I will be conducting as principal investigator in TUBITAK ARDEB 1003 priority area calls has been accepted for funding. In the project, Dr. Lutfi Taner Tunc (Sabanci University, IMC-CTCE) will be the supervisor of the robotics&manufacturing area; and Dr. Bertan Beylergil (Alanya Alaaddin Keykubat University) and Dr. Cem Ozturk (Kordsa A.S.) will be conducting the sub-projects, respectively.

Our project will be focusing on atmospheric plasma activation as an environment-friendly, economic and efficient method for surface treatment of high-performance composite materials used in aeronautics&aerospace applications.

284 proposals were submitted nationwide for the 1st stage of evaluation only under MAG (Engineering Research Group) section, and 17 of them are accepted after a long evaluation procedure, 4 of which belongs to our research center. Congratulations to my 3 colleagues whose proposals were also accepted (Prof. Bahattin Koc, Dr. Burcu Saner Okan, Dr. Eralp Demir; all from Sabanci University, IMC-CTCE).

The project duration is 3 years and the budget is 2.500.000 TL.